Via Umberto Dianda 195/D

55100, San Pietro a Vico – Lucca

+39 0583 467931

+390583471568

[email protected]

P.IVA 01930030463

55100, San Pietro a Vico – Lucca

+39 0583 467931

+390583471568

[email protected]

P.IVA 01930030463

Home » MECHANICAL MACHINING

High-precision components are possible thanks to a long production process with several steps that require skills, experience and high level of specialization.

We normally adopt a step by step method to guarantee the correct monitoring of the entire process, from budgeting up to delivery.

It’s the essential starting point for the production of every components. It’s a document created by the customer’s design office, showing all the indications for its realization such as materials and treatments. Technical design allows us to do a quotation which, once confirmed, turns into an order.

It’s a document created by the customer’s design office, showing all the indications for its realization such as materials and treatments. Technical design allows us to do a quotation which, once confirmed, turns into an order.

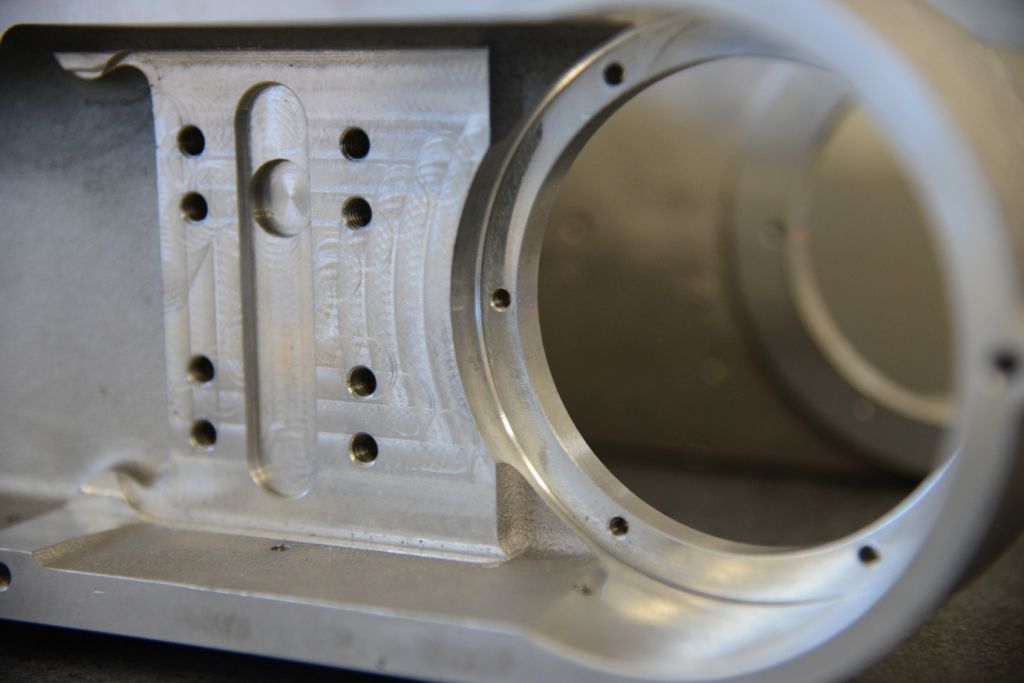

This step begins by positioning the rough piece inside the machine. The entire operation is carried out by one of our expert staff members, who accurately arrange the piece inside the machine. This step also represents the first quality check along the entire production process.

Our 3 and 5-axis CNC work machines realize the component. This step is the most important one because it also represents the first dimensional inspection that our employee does directly on the machine.

Our strict quality method also considers an intermediate check before the finishing. Once it is positive, the component pass to the accessory machining that guarantees the correct finishing and all the treatments required by the customer such as zinc plating, painting, anodizing, etc. or special fillings such as tugsteno carbide, teflon etc.

Once the production process is completed, the machine operator assigns the component to quality control. Our Metrology room with Zeiss technology for three-dimensional control, as well as micrometres, altimeter and roughness tester, measure the components, guaranteeing the right standard required by the technical design.

If necessary, the component follows a final finishing process to remove errors or differences from the original design. The component is now ready for the final check carried out by an expert quality control operator.

The final product is now completely compliant to the customer’s design and it’s ready to be delivered. Our 3 and 5-axis CNC machines connected to the latest generation CAD-CAM software and the high professionalism of our team, guarantee the best quality and productive standards.

Wire and sinker EDM allow us to work with every kind of conductive material and with every geometrical shape, thanks to the possibility to work through the interpolation of the 4th axis and using the fifth one (Z axis) in positioning.

Precision milling is a shavings removal process, which allows us to obtain mechanical components from a rotating shaping machinery, keeping fixed by vises and clamps. Very complex profiles can be obtained by milling process.

Precision turning is a shavings removal mechanical process by a combination of machine and component rotating movements, where the sharpening machine removes the material in excess.

The accessory machining guarantees the correct finishing and all the treatments required by the customer such as welding, micro shot peening and grinding.

Meccanica Precisa blend innovation and experience

Within our structure, automation and professional skills are combined to create mechanical components tailored to the customer needs. Our machinery allows us to carry out different types of manufacturing, both automated and with our expert staff members.